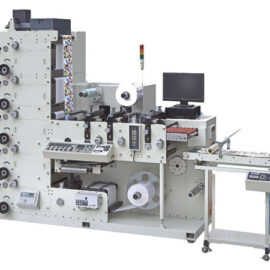

CHARACTERISTICS:

- Upper web pass design structure reduces the plate roller and anilox position thereby reducing overall printing group center of gravity, equipment run more smoothly, completely overcome the ground of dust, ink splash, ink

leaks, that affect printed product. - Fully enclosed doctor blade system, that is to overcome the ink splash, ink leaking and saving more ink, can accurately control the amount of ink supply, and further improving the printing quality.

- Water base ink printing, no pollution, compliance with international printing standard.

- Color printing group from 1 color – 15 color, can be any combination.

- Printing unit adopt high precision imported gear box for driving, fast speed and high efficiency.

- High-precision tension sensor closed loop constant tension designed to ensure accurate and stable printing tension.

- Automatic register control, high accuracy and stability.

- G.E.R. Fife high-performance correction system ( web guide ), ensure that the running of the substrate linear stability and winding the finished product, the end face of uniformity.

- Adjustable inner recycled air for heating system, high efficiency and save energy.

- High-definition color still pictures, to facilitate the printing quality observation.

- The center Control Panel, easy to operate.

- Save paper and material, reduce costs.

MAIN TECHNICAL VARIABLES:

| Model | HRY1000 |

| Max print width | 1000mm |

| Max material width | 1020mm |

| Max speed | 260m/min |

| Max print repeat | 381-1524mm |

| Color group | 4 colors |

| Max unwinder diameter | 1524mm |

| Max rewinder diameter | 1524mm |

| Overprint precision | ± 0.1mm |

| Compress air | ≥0.6Mpa |

| Voltage | 3 phase 380V, 50HZ

Please kindly inform us if different |

| Power | 10.5kw |

| Diameter of air shafts | 76mm

Please kindly inform us if different |

| Diameter of printing plate | 1.7mm

Please kindly inform us if different |

| Diameter of plate mounting tape | 0.38mm

Please kindly inform us if different |