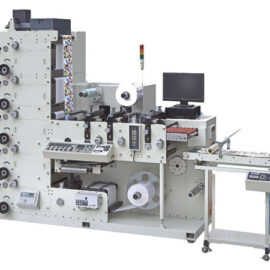

CHARACTERISTICS:

- Adopt the anilox roller to spread ink.

- Unwinding tension is controlled by automatic tension controller from Japan Mitsubishi.

- Each printing unit adopt 360°for registration.

- Each printing unit have one IR dryer

- The rubber roller can break away automatically while parking, and run at a low speed in order to avoid ink being dry.

- The main motor is adopted the import stepless regulation of frequency conversion.

- Unwinding, web guiding, printing, IR drying and rewinding can be finished in one process. This is an ideal machine for printing factory to print many kinds of paper cup.

MAIN TECHNICAL VARIABLES:

|

Printing speed |

60m/min |

|

Printing color |

5colors |

|

Max web width |

860mm |

|

Max printing width |

850mm |

|

Max unwind diameter |

1400mm |

|

Max rewind diameter |

1400mm |

|

Printing girth |

175-355mm or 250-580mm |

|

Overprint Precision |

±0.1mm |

|

Overall dimensions (L×W×H) |

4000×1900×2700mm |

|

Machine weight |

About6000kg |

|

Total power |

20kw |