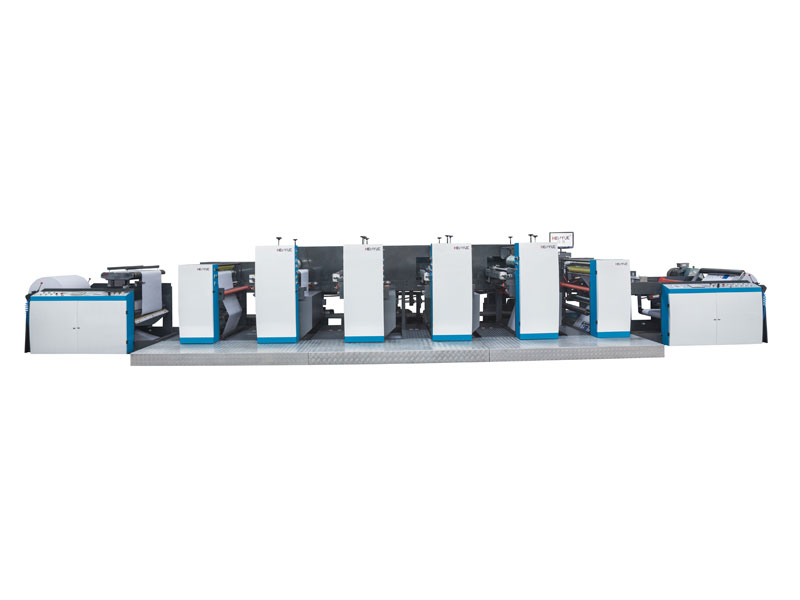

APPLICATION:

-Beverage packaging

-paper cup printing

-food/pharmacy packaging printing

Characteristics:

-Casting board increase machine stability

-Automatic web guiding as standard

-auto tension controller with powder brakes, stable and accurate tension control system

-digital temperature controllers

-printing unit cassette design, anilox roller and cylinder quick change & quick set up

-accurate lateral and circumferential registration

-seperate fast drying for every stage, high efficiency drying capacity

-standard web inspection system, keep inspects printing image

-handy control panel

-pressure between plate cylinder and anilox roller, plate cylinder and pressure roller is pneumatically, easy to adjust pressure

-Air shaft for unwind and rewind

-digital length display and speed display

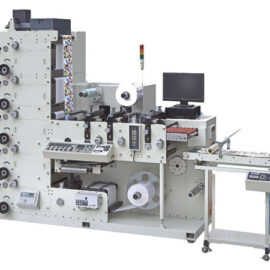

SPECIFICATION:

| Machine model | HRY-1000-4 |

| Max. Web width | 1015mm (39.96″) |

| Max. Printing width | 1000mm (39.37″) |

| Max. Repeat printing length | 241.3-1219mm (9.5″-48″) |

| Repeat die cutting length | 241.3-1219mm (9.5″-48″) |

| Max. Unwind diameter | 1524mm (60″) |

| Max. Rewind diameter | 1524mm (60″) |

| Gear size | 1/8CP |

| Max. speed | 152m/min |

| Main motor drive | 20-30kw |

| Lubrication system | Automatic |

| Air pressure | 0.6Mpa |

| Power supply | 380V, 50Hz, 3Ph |