| Specifications | |

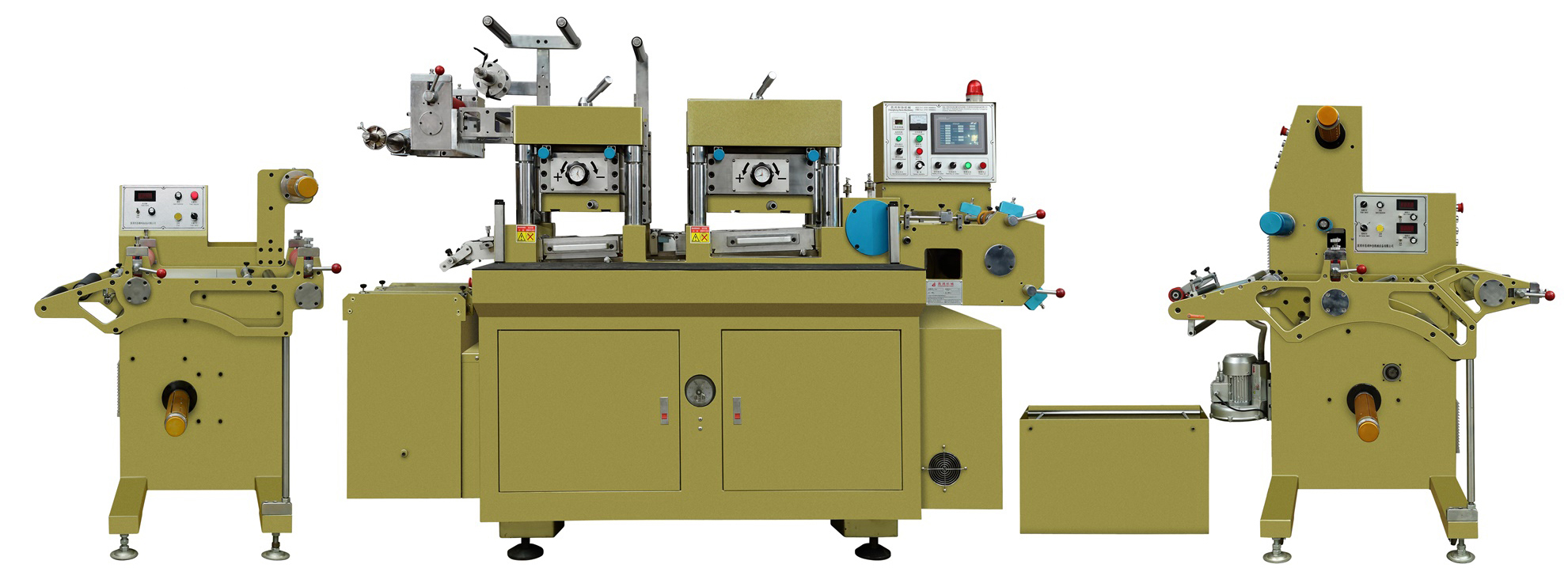

| Model | 320 |

| Max. wed width | 330mm |

| Max. paper length | 390mm/left station 330mm/right station |

| Voltage/current | 380V/32A(3phrase) |

| Gross power | 12kw |

| Machine weight | ≈4000kg |

| Machine speed | 23000time/h |

| Reverse hot stamping speed | 38meter/minute |

| Applicable Blade Height | 7mm-23mm |

| Die cutting precision | ±0.15mm |

| Cushion thickness | 0.5mm-3mm |

| Application material:roll web | <350mm |

| Machine size | 5200*1400*2000mm |

| Max unwinding diameter | 600mm |

| Max winding diameter | 600mm |

| Max die cutting size | 360*315 |

|

Standard configurations |

|

| Feeding machine | 1set |

| Swiri type tension case | 1set |

| Reverse hot stamping unit/hot stamping plate | 1piece |

| Laminated unit | 1set |

| Die cutting upper/lower board | 1set/each |

| Secondary photo cell unit | 1set |

| Wheel press unit | 1set |

| Corundum paper cylinder unit | 1set |

| Horizontal rewinding box | 1piece |

| Horizontal rewinding | 1set |

| Humanized operating platform | 1piece |

FEATURES:

- With CNC driving system and accurate electric eye tracking, simple operation,high efficiency,energy saving and low noise.

- With printing, hot stamping, laminating and die-cutting complete function and stable performance.

- Easy to maintain, automatic supply lubrication system to prevent machine wearing out, suitable for high speed operation.

- Can set any pieces of paper, machine will remind you when it reaches setting number.

- With Japanese servo motor, CNC driving, high printing precision(can make to 0.03mm), eye tracking can multiply print.

- Two feeding types.

SCOPE:

Die cutting machine can use for die cut self-adhesive label, dacron film, laser anti-false label, Punching and mulity compounding on electronic industry, PET, PP, PVC, Viscose, non-woven, insulation materials, shielding materials…etc.